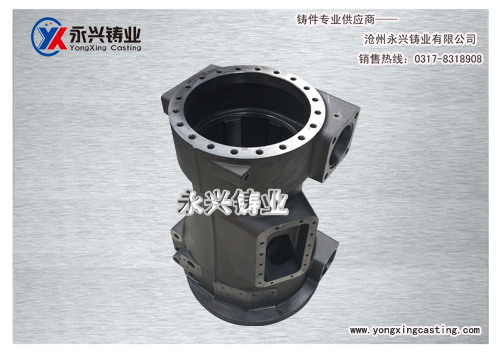

gear boxYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

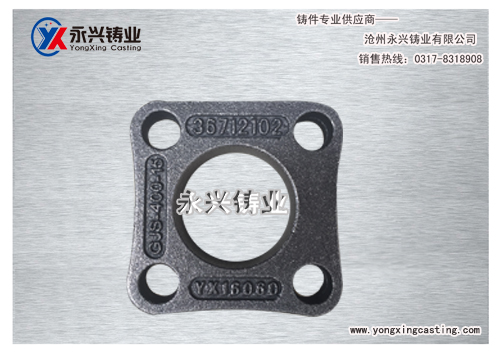

gear boxYongxing foundry is a collection of casting, machining large-scale foundry enterprises... flangeYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

flangeYongxing foundry is a collection of casting, machining large-scale foundry enterprises... cylinder cover Compress castingCasting process:, resin sand, precoated sand Machining : turning/ mill/drill/bore/grin...

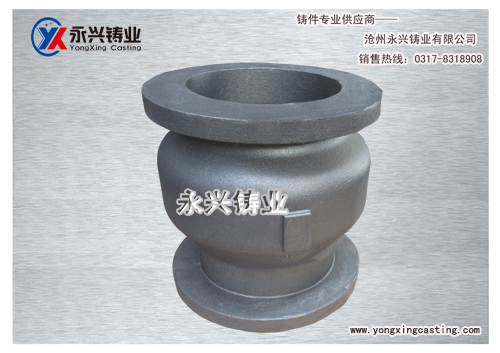

cylinder cover Compress castingCasting process:, resin sand, precoated sand Machining : turning/ mill/drill/bore/grin... valve body castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

valve body castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises... cavityYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

cavityYongxing foundry is a collection of casting, machining large-scale foundry enterprises... elevator castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

elevator castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises... compressor bodyYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

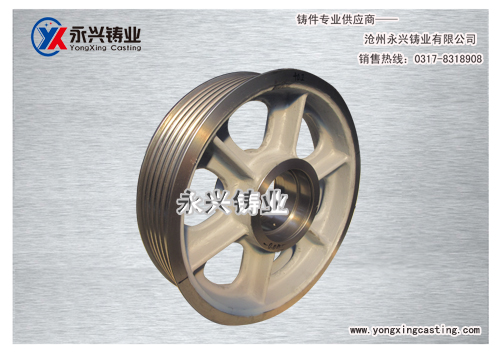

compressor bodyYongxing foundry is a collection of casting, machining large-scale foundry enterprises... oil ringYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

oil ringYongxing foundry is a collection of casting, machining large-scale foundry enterprises...The first is the design craftsmanship of castings. When designing, in addition to determining the geometry and size of the casting according to the working conditions and properties of the metal material, the rationality of the design must

1. The air holes are in the inside of the bed casting, on the surface or near the surface. There are smooth holes with unequal sizes. The shapes are round, long and irregular, and they are single and aggregated. The color is white or dark,

First, the efficiency: efficient furniture can effectively reduce the workpiece in the processing of auxiliary and basic time, the effective work of productivity is to enhance and reduce the overall labor intensity of workers, the more comm

1, good resin sand stiffness, early casting sand strength, which conditions the use of cast iron solidification process of graphitization expansion, effectively eliminating shrinkage \ shrinkage defects, to achieve gray cast iron ductile ir

Casting mainly sand casting and special casting two categories. Ordinary sand casting, the use of sand as a mold material, also known as sand casting, turning sand, including wet sand, dry sand and chemical hardening sand 3 categories, but

Casting is a metal mastery earlier metal thermal processing technology, about 6,000 years of history. From about 1700 BC to 1000 BC, China has entered the heyday of bronze castings, and the process has reached a fairly high level. Casting i

Casting is an industrial technology that shapes liquid metal. In China's traditional foundry industry, the most common foundry technology is sand casting. Sand casting is the casting is generated in the sand, sand casting can produce the mo

1, good resin sand stiffness, early casting sand strength, which conditions the use of cast iron solidification process of graphitization expansion, effectively eliminating shrinkage \ shrinkage defects, to achieve gray cast iron ductile ir

The first is the casting process design. Design, in addition to the working conditions and metal materials to determine the performance of the casting geometry, size, but also from the perspective of casting alloys and casting process chara