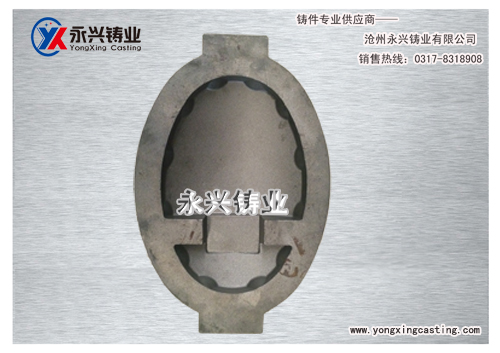

countershaft boxYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

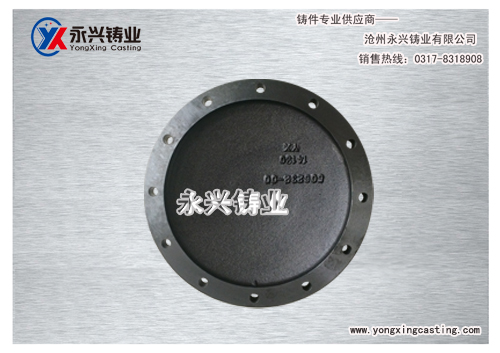

countershaft boxYongxing foundry is a collection of casting, machining large-scale foundry enterprises... valve coverYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

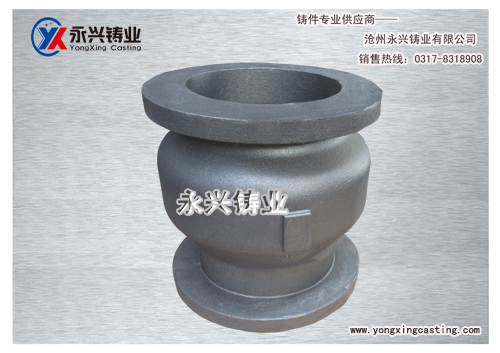

valve coverYongxing foundry is a collection of casting, machining large-scale foundry enterprises... pump bodyYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

pump bodyYongxing foundry is a collection of casting, machining large-scale foundry enterprises... Agricultural machinery spare partYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

Agricultural machinery spare partYongxing foundry is a collection of casting, machining large-scale foundry enterprises... compressor body coverYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

compressor body coverYongxing foundry is a collection of casting, machining large-scale foundry enterprises... cylinder cover Compress castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

cylinder cover Compress castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises... couplingYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

couplingYongxing foundry is a collection of casting, machining large-scale foundry enterprises... valve body castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

valve body castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises...1, good resin sand stiffness, early casting sand strength, which conditions the use of cast iron solidification process of graphitization expansion, effectively eliminating shrinkage \ shrinkage defects, to achieve gray cast iron ductile iron less riser \ No Casting mouth.

2, Real-type casting production using polystyrene foam appearance, the application of furan resin self-hardening sand shape.When the metal liquid poured into the mold, the foam looks quickly under the action of high temperature liquid metal gasification, burning and disappear, metal Liquid replaced the original occupied by the location of foam, solidified into the same shape as the solid cooling castings.

Bed casting casting method selection principle: the preferred cast bed mold sand casting, the main reason is that sand casting than other casting methods, low cost, simple production process, short production cycle. When the wet type can not meet the requirements and then consider the use of clay sand table dry sand, dry sand or other sand. Casting method should be compatible with the production volume, low pressure casting, die casting, centrifugal casting and other casting methods, due to set and mold expensive, so only suitable for mass production, bed castings can be a single casting can also be mass-produced.

The casting method of bed castings generally adopts the process of lost foam casting, resin sand casting, real casting and high grade casting, for example, the bed body, column, cross beam and slide table of the large bed castings are all manufactured by these casting processes .

Casting method of bed castings

Bed casting casting method commonly used sand casting, followed by special casting methods, such as: metal casting, investment casting, gypsum casting. The sand casting can be divided into clay sand, organic binder sand, resin sand, lost foam and so on.