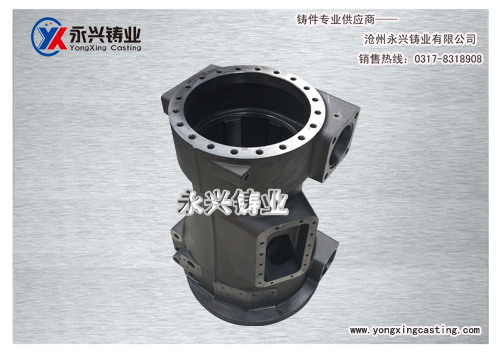

gear boxYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

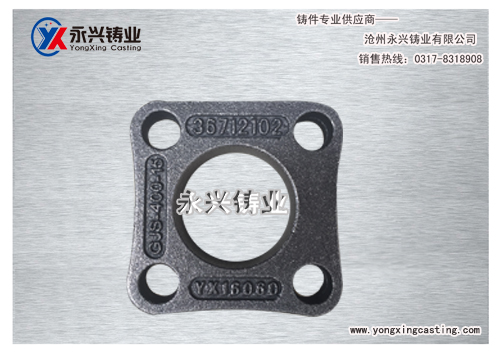

gear boxYongxing foundry is a collection of casting, machining large-scale foundry enterprises... flangeYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

flangeYongxing foundry is a collection of casting, machining large-scale foundry enterprises... cylinder cover Compress castingCasting process:, resin sand, precoated sand Machining : turning/ mill/drill/bore/grin...

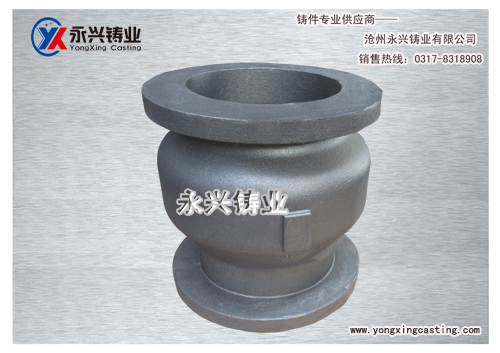

cylinder cover Compress castingCasting process:, resin sand, precoated sand Machining : turning/ mill/drill/bore/grin... valve body castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

valve body castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises... cavityYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

cavityYongxing foundry is a collection of casting, machining large-scale foundry enterprises... elevator castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

elevator castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises... compressor bodyYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

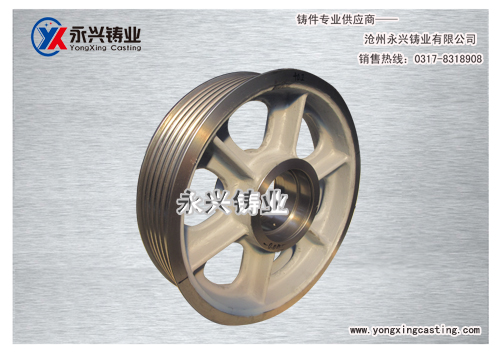

compressor bodyYongxing foundry is a collection of casting, machining large-scale foundry enterprises... oil ringYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

oil ringYongxing foundry is a collection of casting, machining large-scale foundry enterprises...Repair defects in gray iron castings, the repair results of several traditional welding technology in machine tool casting defects. Analysis of the reasons for the poor results of the repair of machine tool castings.

Ball production process of ductile cast iron, heat treatment, blast cleaning or machining often found some diameter is about 0.5-3mm, the shape is spherical, elliptical or needle shaped hole smooth wall holes

Nodular graphite cast iron castings due to its characteristics of the paste solidification of the production of cast iron due to poor shrinkage often produce shrinkage, shrinkage and other defects.

Quality of the machine tool castings including appearance quality, internal quality and service quality.

Lathe bed casting casting method is commonly used is the sand casting, the second is the special casting method, such as: metal mold casting, investment casting, plaster casting etc.

A lathe bed casting, give priority to the mold casting, the main reason is that the cost of the casting mould casting method than other low, simple production process, short production period.

To check on the bed casting 1, machine tool bed casting before painting, the use of tools to reshape the uneven surface, the dirt on the surface to be cleared.

give priority to the mold casting, the main reason is that the cost of the casting mould casting method than other low, simple production process, short production period.

Carbon in cast iron graphite to form precipitation, precipitation of graphite in cast iron if strip when called grey cast iron or gray iron, vermicular cast iron is the name of vermicular graphite cast iron is the name.