axle housingYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

axle housingYongxing foundry is a collection of casting, machining large-scale foundry enterprises... cylinder cover Compress castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

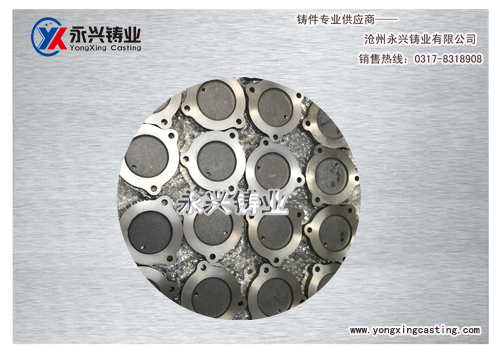

cylinder cover Compress castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises... compressor body coverCasting process:, resin sand, precoated sand Machining : turning/ mill/drill/bore/grin...

compressor body coverCasting process:, resin sand, precoated sand Machining : turning/ mill/drill/bore/grin... half seal compressor body coverYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

half seal compressor body coverYongxing foundry is a collection of casting, machining large-scale foundry enterprises... pump body castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

pump body castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises... hubYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

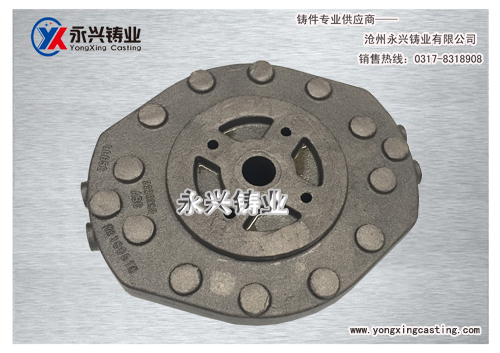

hubYongxing foundry is a collection of casting, machining large-scale foundry enterprises... compressor body coverYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

compressor body coverYongxing foundry is a collection of casting, machining large-scale foundry enterprises... cavityYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

cavityYongxing foundry is a collection of casting, machining large-scale foundry enterprises...Repair defects in gray iron castings, the repair results of several traditional welding technology in machine tool casting defects. Analysis of the reasons for the poor results of the repair of machine tool castings. Through the research on the repairing result of the casting defect repair machine in the machine tool castings, it is confirmed that the new technology and the process of repairing the machine tool castings is indeed feasible. The casting defect repair machine to repair the defects of casting, casting in the repair process, no heating, no deformation, no crack, weld metal density, no hard points and no annealing phenomenon, can be any mechanical processing. Material selection is not restricted by the material, through the choice of different materials, can achieve the welding repair point of the performance, color and the unity of the mother. Reinforcing material and parent material for metallurgical bonding, combined with high strength, will not produce off welding repair quality in line with the quality of casting product quality inspection standards, is worth popularizing widely. But the process of casting defect repair machine welding repair for a range of 1.5- with 1.2mm welding melting point repeatedly stacking, in large area defect repair process, repair efficiency is the only factor that restricts its wide application. For the large defects of machine tool castings, the composite application of traditional welding repair process and casting defect repair machine is recommended.