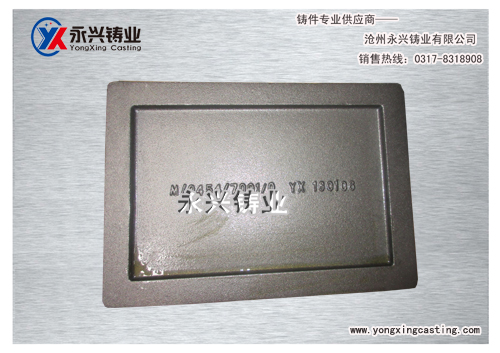

compressor body coverYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

compressor body coverYongxing foundry is a collection of casting, machining large-scale foundry enterprises... compressor body coverYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

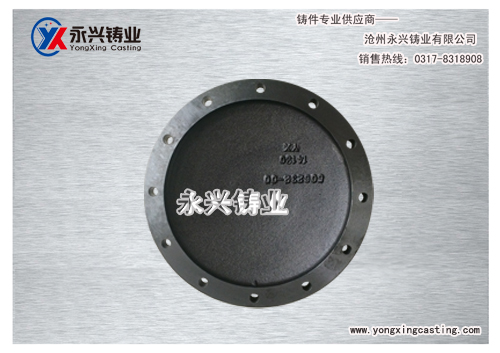

compressor body coverYongxing foundry is a collection of casting, machining large-scale foundry enterprises... gear boxYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

gear boxYongxing foundry is a collection of casting, machining large-scale foundry enterprises... pump body castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

pump body castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises... oil ringYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

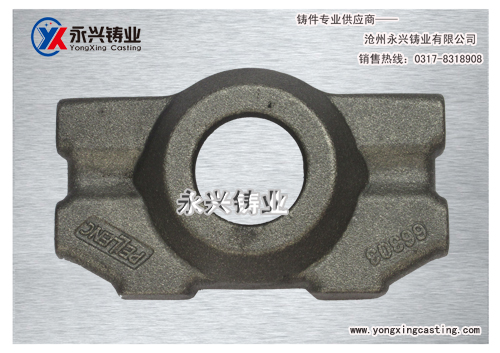

oil ringYongxing foundry is a collection of casting, machining large-scale foundry enterprises... Agricultural machinery spare partYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

Agricultural machinery spare partYongxing foundry is a collection of casting, machining large-scale foundry enterprises... supportYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

supportYongxing foundry is a collection of casting, machining large-scale foundry enterprises... cavityYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

cavityYongxing foundry is a collection of casting, machining large-scale foundry enterprises...Casting mainly sand casting and special casting two categories.

Ordinary sand casting, the use of sand as a mold material, also known as sand casting, turning sand, including wet sand, dry sand and chemical hardening sand 3 categories, but not all sand can be used for casting. The advantage is that the cost is lower because the sand used in the mold can be reused; the disadvantage is that the mold is time consuming, the mold itself can not be reused, and the finished product must be destroyed before it can be destroyed.

1. Sand (core) casting methods: wet sand, resin sand, sodium silicate dry and dry-type, real casting, negative pressure modeling.

2. Sand core manufacturing methods: Sand core size, shape, production volume and specific production conditions to choose from. In production, can be divided into hand-made core and machine core.

Special casting, according to the molding material can be divided into natural mineral sand as the main molding material for the special casting (such as investment casting, mud casting, shell casting, negative pressure casting, real casting, ceramic casting, etc.) and Metal casting as the main type of special casting (such as metal casting, pressure casting, continuous casting, low pressure casting, centrifugal casting, etc.) two categories.

Dewaxing casting method

This method can be outer film casting method and solid casting method.

The desired object to be cast is first waxed and then immersed in a ceramic (or silica sol) containing bath and allowed to dry, so that the waxed replica is covered with a ceramic outer membrane, repeating the steps until the outer membrane is sufficient to support casting Process (about 1/4 inch to 1/8 inch), then dissolve the wax in the mold and pull it away from the mold. Subsequent molds need to be repeatedly high temperature, increased hardness before casting.

This method has good accuracy, but also can be used as high melting point metal (such as titanium) casting. However, due to the high price of ceramics, and the production needs multiple heating and complexity, it is quite expensive.

Metal mold casting method

Molds are made of metal having a higher melting point than the starting material. Which is broken down into gravity casting method, low pressure casting method and high pressure casting method.

Subject to the melting point of the mold, the metal that can be cast is also limited.