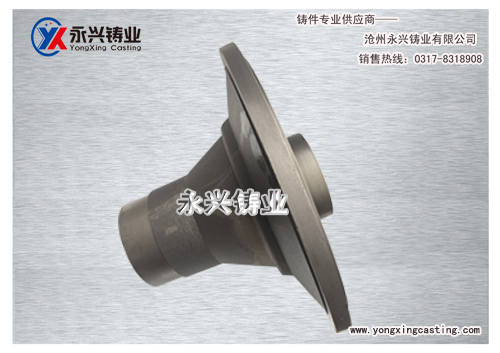

hubYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

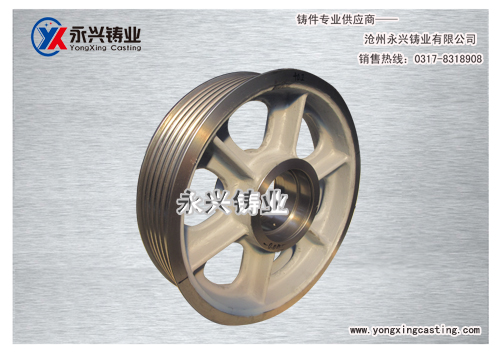

hubYongxing foundry is a collection of casting, machining large-scale foundry enterprises... statorYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

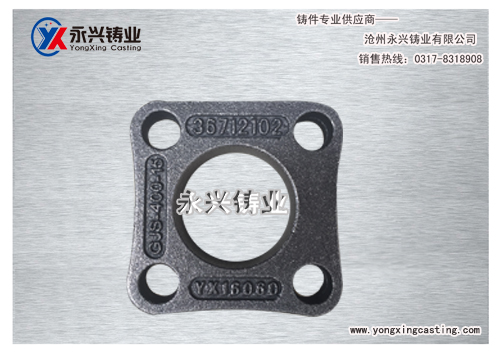

statorYongxing foundry is a collection of casting, machining large-scale foundry enterprises... elevator castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

elevator castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises... compressor body coverYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

compressor body coverYongxing foundry is a collection of casting, machining large-scale foundry enterprises... shifting forkYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

shifting forkYongxing foundry is a collection of casting, machining large-scale foundry enterprises... housing level sensorYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

housing level sensorYongxing foundry is a collection of casting, machining large-scale foundry enterprises... brake armYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

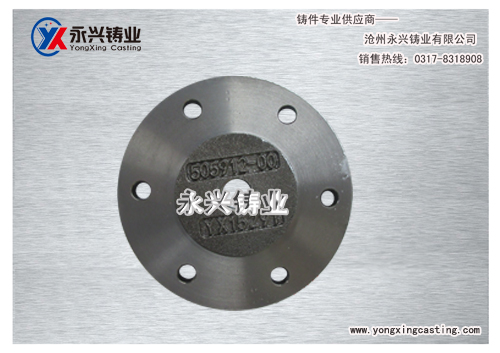

brake armYongxing foundry is a collection of casting, machining large-scale foundry enterprises... flangeYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

flangeYongxing foundry is a collection of casting, machining large-scale foundry enterprises...Casting production is an old and emerging industry, but also an important base industry in the machinery industry. Determines the service life of the equipment and the use of reliability. Through thousands of years of production practice accumulation, scientific research, from the macro to deep into the micro-theory, with great development, continue to reveal the casting process, the stability of the completion of technical parameters control, you can ensure the use of castings to ensure that Mechanical equipment life, the use of reliability.

To produce high-quality castings, we first need to study the factors that affect the performance of cast iron, that is, how to improve the purity of molten iron melt: how to get a good graphite form; chemical composition of the scope of control, to solve the problem of technical control parameters And to study what smelting methods are used to achieve their goals.

Control of the purity of molten iron:

1. Oxide inclusions produced by oxidative burns;

2. Melting pores produced by melting oxygen;

3. Control of sulfur content to prevent the generation of sulfur eutectics;

4. Control of phosphorus content to prevent the production of phosphorus eutectics;

5. Limit the trace element content below the amount of interference.

Hot metal smelting process control:

1. Control of molten iron oxidation;

2. Eliminate the graphite heredity, get a good graphite form;

3. Control the chemical composition of the fluctuation range, access to accurate chemical composition;

4. Control of molten iron melting temperature;

5. Optimum smelting method selection and corresponding equipment system.