hubYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

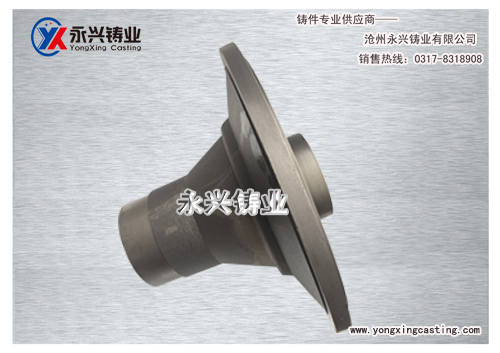

hubYongxing foundry is a collection of casting, machining large-scale foundry enterprises... compressor body coverCasting process:, resin sand, precoated sand Machining : turning/ mill/drill/bore/grin...

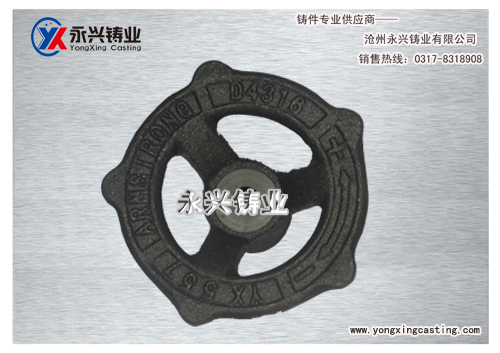

compressor body coverCasting process:, resin sand, precoated sand Machining : turning/ mill/drill/bore/grin... hand wheelYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

hand wheelYongxing foundry is a collection of casting, machining large-scale foundry enterprises... cavityYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

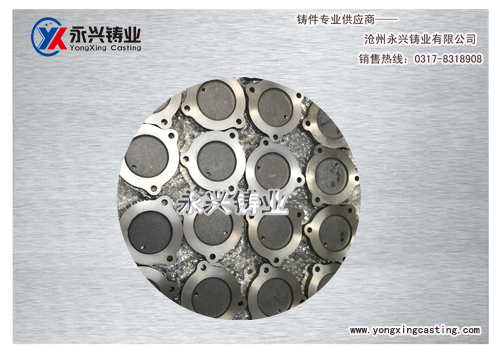

cavityYongxing foundry is a collection of casting, machining large-scale foundry enterprises... pump body castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

pump body castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises... compressor bodyYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

compressor bodyYongxing foundry is a collection of casting, machining large-scale foundry enterprises... spring baseYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

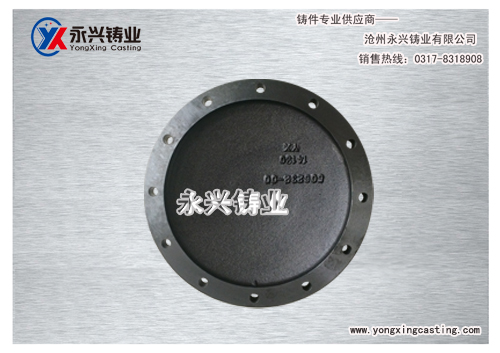

spring baseYongxing foundry is a collection of casting, machining large-scale foundry enterprises... compressor body coverYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

compressor body coverYongxing foundry is a collection of casting, machining large-scale foundry enterprises...Casting is a multi-process, multi-operation of the type of work, so in any one part of the problem, will lead to the occurrence of defects, really "a chess full disk are lost" may. On-site inspection of the project is mainly the model of cleaning, cavity paint flow marks, transport sand, the quality of the basin, especially the examination of the mouth is particularly important.

(1) to modify the riser parameters, because the piece has a thin this particularity, we in the early thin-walled castings in practice and theory are not enough to understand, resulting in the design of the riser did not take into account its particularity, The loose loose.

(2) the use of appropriate pouring temperature to reduce the liquid shrinkage value asked. The pouring temperature is controlled between 1380 ° C and 1360 ° C.

(3) site control, strengthen the process control and assessment of the combination. According to the quality of the riser will be changed to two 10 insulation riser, riser pad design for the special riser pad.