countershaft boxYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

countershaft boxYongxing foundry is a collection of casting, machining large-scale foundry enterprises... baseplateYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

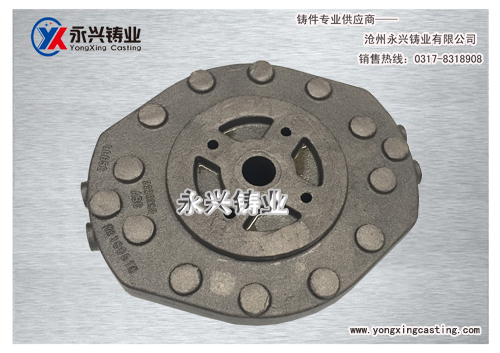

baseplateYongxing foundry is a collection of casting, machining large-scale foundry enterprises... cylinder cover Compress castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

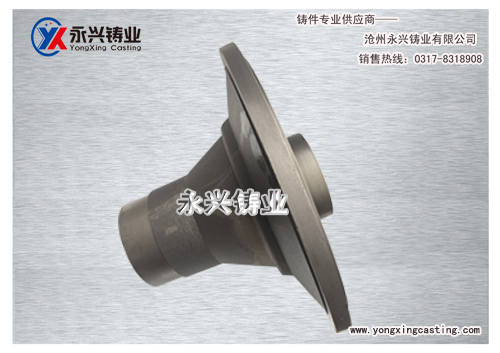

cylinder cover Compress castingYongxing foundry is a collection of casting, machining large-scale foundry enterprises... hubYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

hubYongxing foundry is a collection of casting, machining large-scale foundry enterprises... Agricultural machinery spare partYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

Agricultural machinery spare partYongxing foundry is a collection of casting, machining large-scale foundry enterprises... brake armYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

brake armYongxing foundry is a collection of casting, machining large-scale foundry enterprises... hubYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

hubYongxing foundry is a collection of casting, machining large-scale foundry enterprises... oil ringYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

oil ringYongxing foundry is a collection of casting, machining large-scale foundry enterprises...After heat treatment of gray cast iron can only change the matrix structure, can not change the shape of graphite. So it is impossible to improve the mechanical properties of gray cast iron. Heat treatment of gray cast iron is mainly used to eliminate casting stress and white tissue, stable size, improve the machining performance, improve the surface hardness and wear resistance etc..

Stress relieving annealing

In order to eliminate the casting stress caused by the uneven cooling of the casting during the solidification process, the deformation and the crack of the casting are prevented. The casting process is heated to 500~600 DEG C, holding time with furnace cooling to 150~200 deg.c followed by air cooling, the casting is sometimes placed for a long period of time in the natural environment, the casting stress relaxation, this method is called "natural aging", a large gray cast iron can be used this way eliminate casting stress.

Graphite annealing

In order to eliminate white tissue, reduce hardness and improve the cutting performance. The casting method is heated to 850~900 DEG C, heat 2~5 hours, and then with the furnace cooling to 400~500 deg.c, then released air cooling, make cementite in the insulation and decomposition in the process of cold formed graphite.

Surface hardening

Increase surface hardness and prolong service life. If the working surface of the inner surface of the machine tool guide rail and the inner wall of the internal combustion engine cylinder liner, the high hardness and wear resistance performance, the surface quenching method can be adopted. Commonly used methods have high (medium) frequency induction heating surface hardening and contact resistance heating surface quenching.