shifting forkYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

shifting forkYongxing foundry is a collection of casting, machining large-scale foundry enterprises... coil boxYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

coil boxYongxing foundry is a collection of casting, machining large-scale foundry enterprises... cylinder cover Compress castingCasting process:, resin sand, precoated sand Machining : turning/ mill/drill/bore/grin...

cylinder cover Compress castingCasting process:, resin sand, precoated sand Machining : turning/ mill/drill/bore/grin... hubYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

hubYongxing foundry is a collection of casting, machining large-scale foundry enterprises... compressor bodyYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

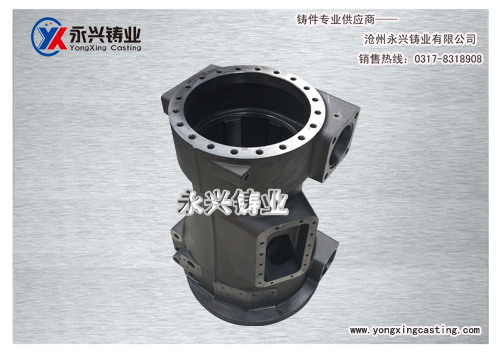

compressor bodyYongxing foundry is a collection of casting, machining large-scale foundry enterprises... couplingYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

couplingYongxing foundry is a collection of casting, machining large-scale foundry enterprises... valve coverYongxing foundry is a collection of casting, machining large-scale foundry enterprises...

valve coverYongxing foundry is a collection of casting, machining large-scale foundry enterprises... compressor body coverCasting process:, resin sand, precoated sand Machining : turning/ mill/drill/bore/grin...

compressor body coverCasting process:, resin sand, precoated sand Machining : turning/ mill/drill/bore/grin...Valve body material according to different process media, the use of different materials. Commonly used materials are: cast iron, cast steel, stainless steel, carbon steel, plastic, copper, etc..

1. Gray cast iron

Gray cast iron valve with its low price, wide application in all fields of industry. They are commonly used in the case of water, steam, oil and gas, and are widely used in chemical, printing and dyeing, oil, textiles and many other industrial products that have little or no impact on iron pollution. Suitable for working temperature between 15~200 DEG C, low pressure valve nominal pressure PN is less than 1.6MPa.

2. Nodular graphite cast iron

Nodular graphite cast iron is a kind of cast iron, which replaces the flake graphite in gray cast iron. This change in the structure of the metal makes its mechanical properties better than that of the ordinary gray cast iron, and does not damage other properties. Therefore, the use of ductile iron valves than those used in the production of gray cast iron valve to use higher pressure. Suitable for working temperature between 30~350 DEG C, nominal pressure PN is less than or equal to 4.0MPa in the low pressure valve. Suitable medium for water, sea water, steam, air, gas, oil, etc..

3. carbon steel

At first the development of cast steel is to meet the needs of the production of the capacity of the cast iron and bronze valves. But due to the use of the good performance of carbon steel valve, and the resistance strength stress on by thermal expansion, impact load and deformation of pipeline, makes its use scope, usually including the use of cast steel valves and bronze valve operating conditions. Middle and high pressure valve suitable for working temperature at - 29~425. Among them, 30Mn, 40~400 as the temperature is - 16Mn degrees Celsius, commonly used to replace the A105 ASTM. Applicable medium for saturated steam and superheated steam. High temperature and low temperature oil, liquefied gas, compressed air, water, gas, etc..